Semiconductor fabrication demands precision, consistency, and speed. In plasma etching and thin film processes, nanometer-level control directly impacts yield and device performance. Yet many fabs still rely on manual tuning and trial-based experimentation to reach optimal results. Each wafer run generates valuable process data such as chamber pressure, RF power, gas flows, temperature, and time, but much of this data remains underutilized. This article presents a machine learning (ML) solution that transforms historical process data into accurate, real-time predictions of plasma etch rates. Using a neural network trained on key operating conditions, we developed a surrogate model that consistently achieves sub-angstrom error and predicts etch outcomes with over 97% of results falling within ±5 Å/min of actual values. The model enables predictive tuning without interrupting production, replacing costly experimentation with fast, data-driven insights. This approach offers fabs a smarter, faster, and more agile method for process control. Semiconductor leaders can now convert legacy process data into strategic insights, accelerate development cycles, and unlock new efficiencies in plasma-based manufacturing.

Industry Context

Challenges in Plasma Etching and Thin Film Processing

Plasma etching is a cornerstone of semiconductor manufacturing. It enables the creation of complex nanoscale patterns on silicon wafers by precisely removing layers of material (Lam Research, n.d.). However, the process is highly sensitive to chamber conditions, recipe parameters, and tool aging effects. Minor fluctuations in RF power, gas flow rates, pressure, or temperature can significantly impact critical metrics such as etch rate, anisotropy, and uniformity (Wikipedia, 2025).

Traditionally, achieving optimal results requires extensive experimentation, often guided by a design-of-experiments (DOE) matrix. Process engineers iterate across multiple wafer runs, manually tuning parameters and analyzing results post-run. This time-intensive loop delays yield ramp-up and increases development costs. Despite advances in sensor instrumentation and data logging, much of the collected process data is used reactively rather than proactively.

With ongoing device scaling and tighter design rules, the margin for error continues to shrink. Engineers must contend with increasing complexity in high-aspect-ratio etching, evolving material stacks, and stringent critical dimension (CD) control—all while maintaining competitive cost structures. The situation is further complicated by global supply pressures and demand for faster development cycles (Lam Research, 2024). Leading equipment manufacturers, such as Applied Materials, have developed advanced etch systems like the Centris® Sym3® Etch platform to address these challenges, offering improved process control and uniformity for high-volume manufacturing (Applied Materials, n.d.).

Fabs today collect terabytes of process data each month. However, this data is rarely used for predictive control. Existing models, often empirical or physics-based, can take weeks or months to calibrate—even when aided by statistical process control (SPC) techniques. Machine learning offers a new opportunity: by training models on historical DOE results, SPC trends, and sensor logs, ML-based surrogate models can deliver fast, accurate predictions that adapt to real-time input conditions. These data-driven models reduce the need for physical experiments and unlock deeper insights into process behavior and optimization potential.

The Opportunity

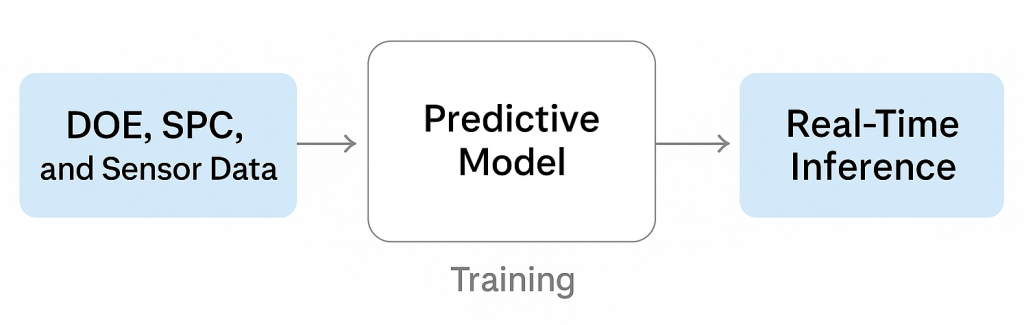

Turning DOE, SPC, and sensor data into predictive ML models

Machine learning presents a practical and scalable path to unlock deeper insight from the process data fabs already collect—without overhauling existing systems. Structured results from DOE matrices, parameter trends from SPC charts, and live sensor outputs from etch chambers can all serve as high-value training data for predictive models.

Rather than relying solely on static, physics-based models, an ML-driven surrogate model can learn directly from historical patterns and complex variable interactions. For example, a neural network trained on past DOE outcomes can rapidly infer etch rates for new parameter combinations—bypassing the need for repeated wafer runs. Similarly, integrating SPC trends allows the model to adjust to tool drift or seasonal shifts in performance.

Once trained, the model can be deployed for real-time inference. Engineers can use it to simulate recipe changes, optimize parameter windows, or monitor process health with predictive accuracy. This enables virtual experimentation and just-in-time tuning, dramatically reducing development cycles and wafer scrap.

More importantly, these models can evolve continuously. As new runs generate fresh data, the model can be retrained or fine-tuned—improving its accuracy and robustness over time. For fabs seeking higher throughput, tighter control, and reduced variability, machine learning transforms passive data archives into active process intelligence.

Model Development

Building a Surrogate ML Model

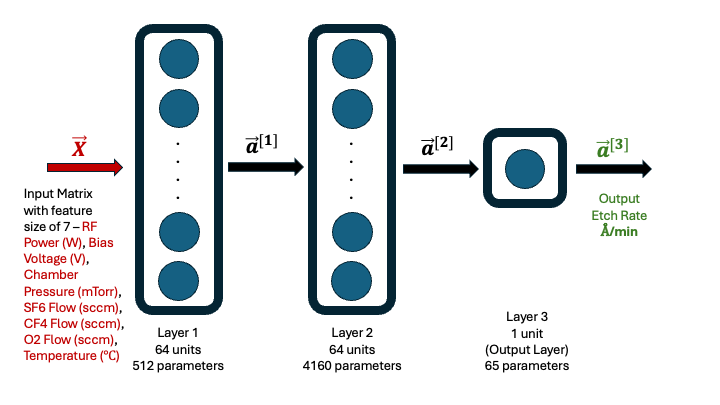

The neural network architecture used for this study is illustrated below. It consists of three fully connected layers with a total of 4,737 trainable parameters. The input layer takes in a feature vector of size 7, derived from key controllable parameters in plasma etching. The output is a single value representing the predicted etch rate (ER) in units of Ångström per minute.

In the absence of real fab data from DOE, SPC, or sensor logs, a synthetic dataset was generated using a well-structured equation inspired by formulations published in semiconductor process literature. The equation captures how etch rate (ER) depends on plasma process conditions through a combination of power-law and Arrhenius-like relationships:

The empirical constants were set at 0.8, 1.0, 0.5, 0.6, 0.4, and 0.3 respectively.

are the activation energy (0.5 eV) and universal gas constant (8.617×10-5 eV/K) respectively.

are the controllable process variables – plasma power (W), bias voltage (V), pressure (mTorr), flow rates of gases (sccm) and temperature (C, converted to K) respectively.

These input features were randomly varied within physically realistic bounds to generate the synthetic dataset, with corresponding etch rates computed from the above expression. This approach provided a self-consistent dataset suitable for training and evaluating the ML model in a surrogate learning context.

The synthetic dataset comprised 1,000 feature sets, each representing a unique combination of plasma etching process parameters. The corresponding etch rates were computed using the surrogate equation described earlier.

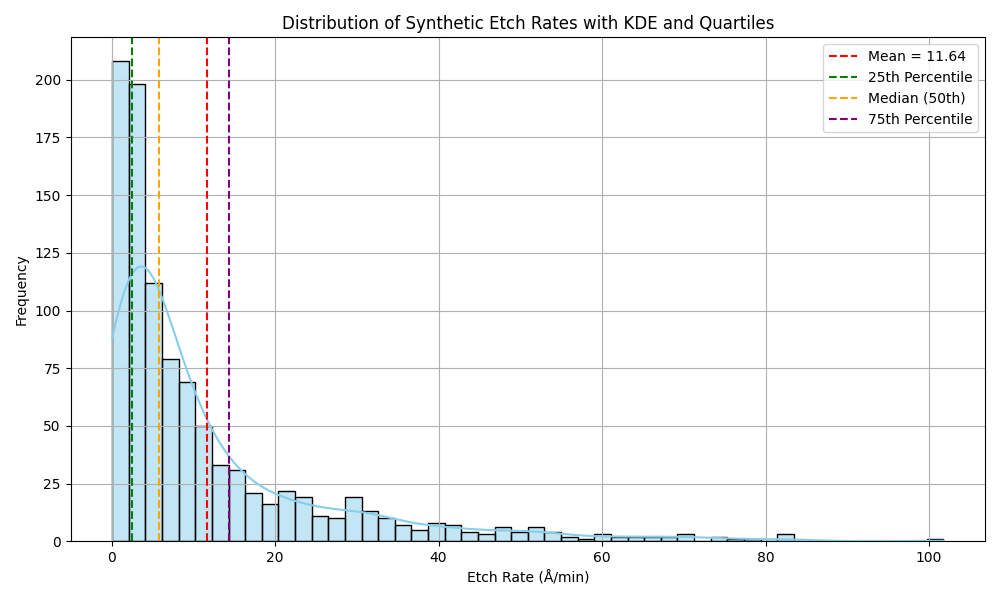

The histogram below illustrates the distribution of the computed etch rates across the full range of feature sets. As expected, the distribution reflects the non-linear dependence of etch rate on process parameters, resulting in a skewed pattern typical of many plasma process outcomes. This variability makes the dataset well-suited for training and testing the neural network model, providing a robust challenge that mirrors real-world process complexity.

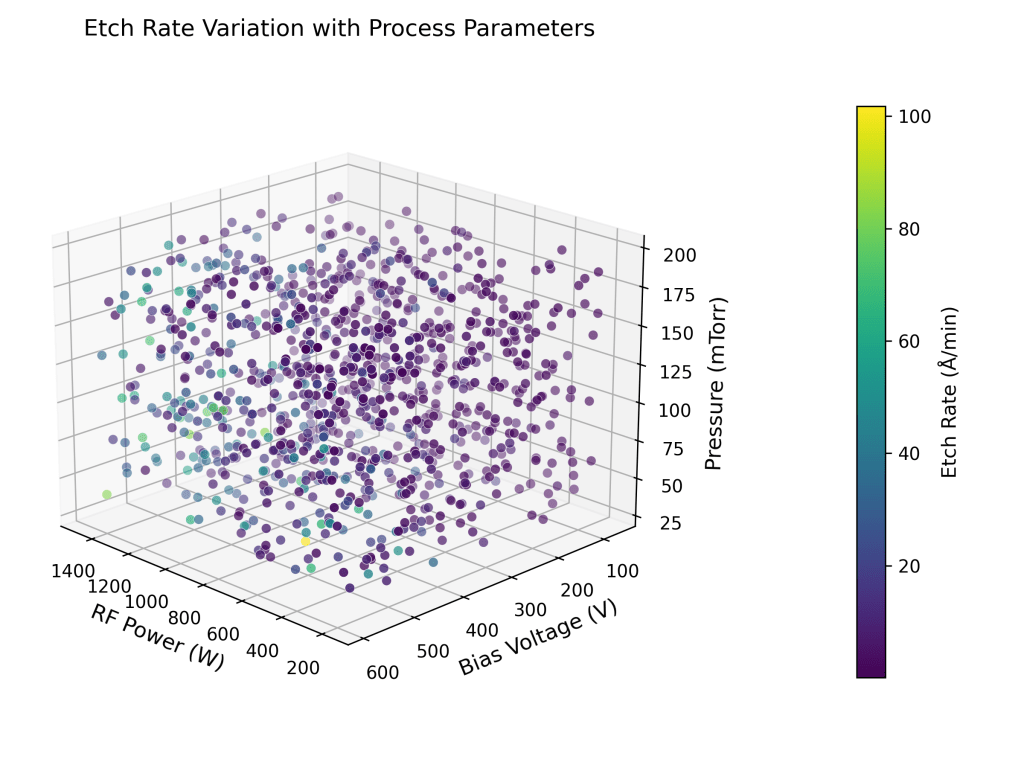

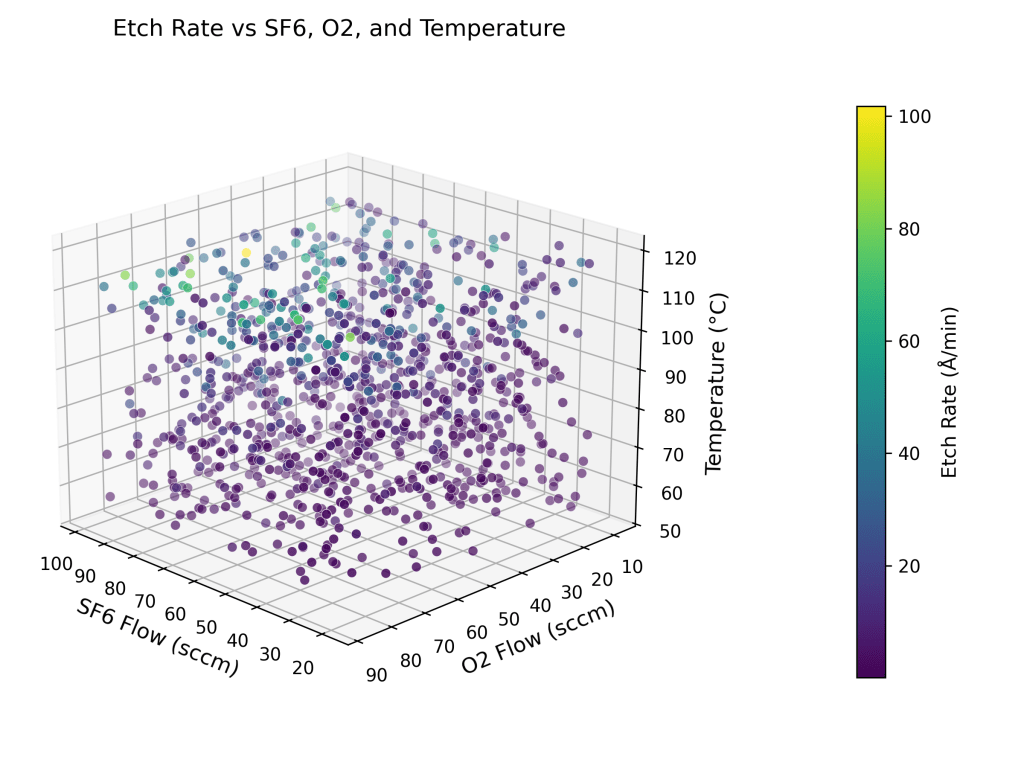

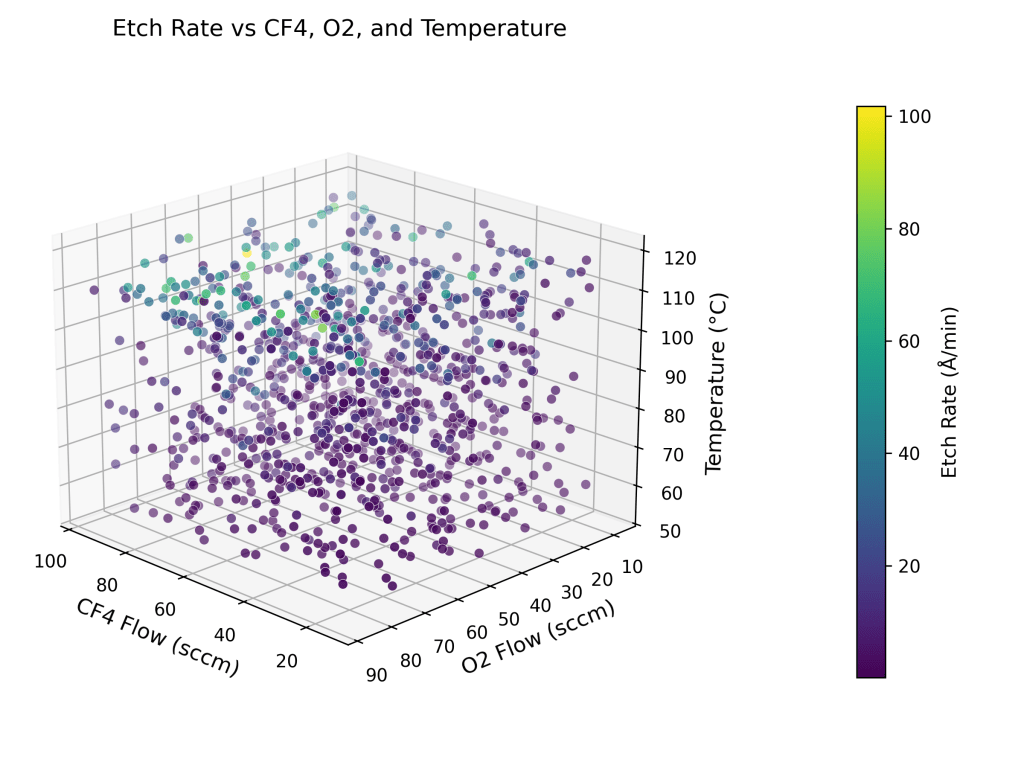

To further visualize the relationship between etch rate and input parameters, three 3D scatter plots are presented below. Each plot highlights how the etch rate varies as a function of key process variables across different parameter combinations. These visualizations offer intuitive insights into the multivariate dependencies that the neural network model is designed to learn and predict.

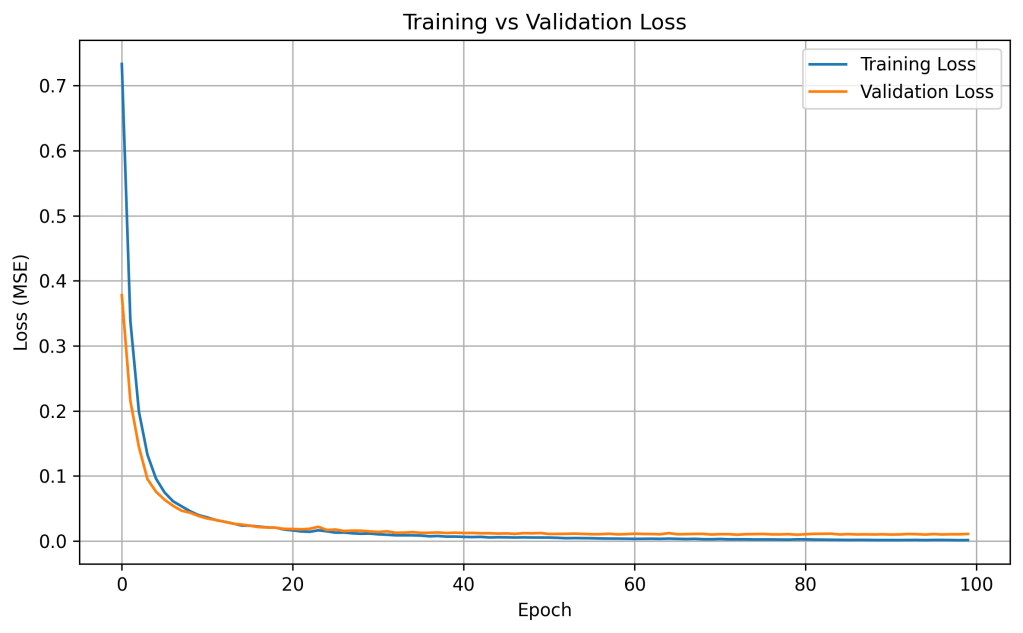

The neural network model was developed in Python using the TensorFlow library. All dense layers employed the ReLU activation function and the Adam optimizer, with mean squared error (MSE) as the loss function. The synthetic dataset was split 80:20 into training and testing subsets. During training, the model exhibited stable convergence, as shown in the loss curve below.

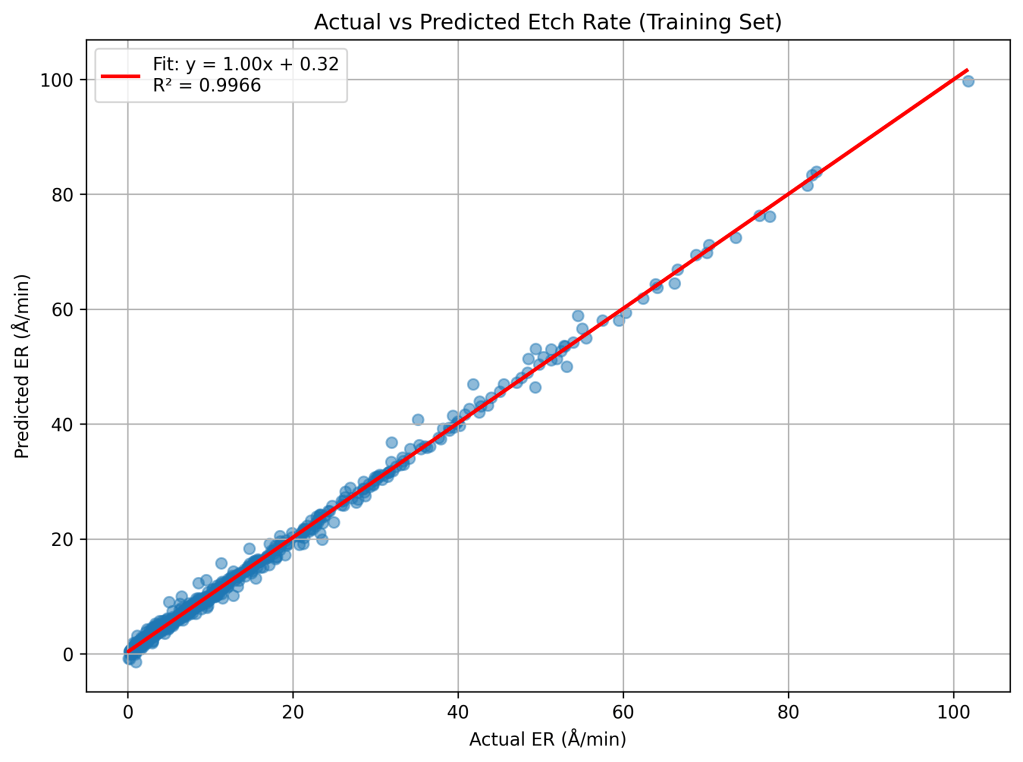

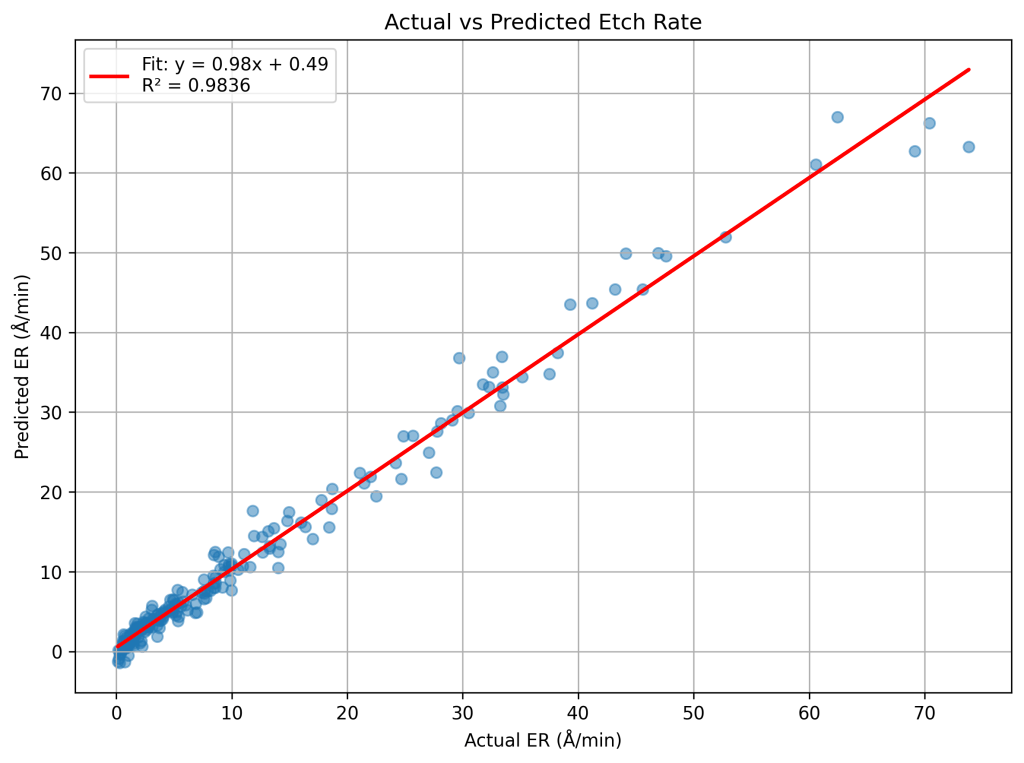

The final training performance achieved an R2 of 0.9966, MSE of 0.7459, and root mean square error (RMSE) of 0.8636 Å/min. This is an excellent fit with near unity slope.

The model also demonstrated strong generalization to unseen data. On the test set, the neural network achieved an R2 of 0.9836, MSE of 3.4895, and RMSE of 1.8680 Å/min, with the regression fit again closely matching a unity slope.

Overall, the model achieved sub-angstrom accuracy across the full etch rate range during training and maintained RMSE under 2 Å/min on test data. This level of precision aligns with the resolution limits of physical metrology tools used in semiconductor fabrication, underscoring the model’s practical value as a predictive tool for low-rate plasma etching applications.

Results: Accuracy and Optimization Potential

Validating predictive performance and enabling virtual process optimization

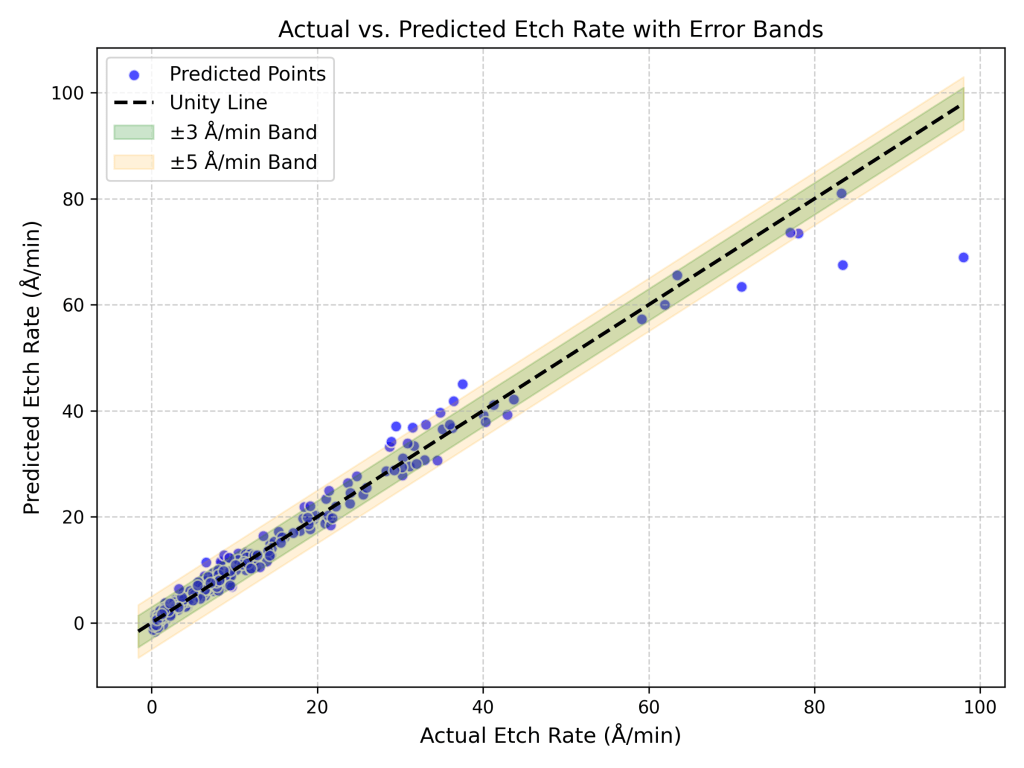

The neural network model demonstrated high predictive accuracy across both the original training/testing dataset and a newly generated set of unseen test data.

Performance on new test data

To evaluate the model’s generalization ability, a fresh set of 300 synthetic feature sets was created, covering the same process parameter ranges used during training. The model’s predictions on this new data yielded the following results:

- Mean Absolute Error (MAE): 1.29 Å/min

- Maximum Absolute Error: 29.06 Å/min

- 92.67% of predictions within ±3 Å/min

- 97.33% of predictions within ±5 Å/min

The scatter plot below compares the actual and predicted etch rates, with shaded error bands at ±3 Å/min and ±5 Å/min. The majority of predictions fall within these bands, especially for etch rates below 80 Å/min, which represents the primary process window of interest for many plasma etching applications.

Optimization potential

This level of accuracy makes the neural network model a viable surrogate model for process optimization tasks:

- Virtual recipe tuning: Engineers can predict outcomes for new parameter combinations without running physical experiments.

- Parameter screening: Potentially viable process windows can be identified quickly, reducing experimental overhead.

- Real-time recommendations: Once deployed, the model can suggest operating points likely to meet target etch rates, improving process agility.

Real-time recommendations: Once deployed, the model can suggest operating points likely to meet target etch rates, improving process agility.

- Accelerate development cycles

- Reduce wafer losses due to suboptimal tuning

- Lower process development costs

The surrogate model’s strong performance in both interpolation and slight extrapolation scenarios indicates its robustness and practical utility in semiconductor process engineering environments.

Implications for Semiconductor Manufacturing

Leveraging ML models for real-time control, virtual experiments, and digital twins

The demonstrated surrogate model, with its validated accuracy and robustness, has clear implications for advancing semiconductor process development and control.

Real-Time Feedback Control

By integrating the trained neural network into process control systems, fabs can:

- Predict etch rate outcomes in real time as process parameters vary.

- Detect drift or tool variability before it impacts yield.

- Recommend parameter adjustments to maintain target etch rates without interrupting production.

Virtual Experiments and Parameter Tuning

The model enables virtual design of experiments (vDOE), allowing engineers to:

- Explore process windows computationally, reducing the need for costly wafer runs.

- Evaluate “what-if” scenarios quickly when adjusting RF power, bias voltage, gas flows, or other parameters.

- Optimize recipes while minimizing development time and experimental expense.

Digital Twins of Plasma Systems

This surrogate model can serve as a foundational element in building digital twins for plasma etch chambers:

- Pairing real-time process data with predictive models allows continuous monitoring and optimization.

- Virtual twins can simulate outcomes for new device architectures or material stacks without hardware modifications.

- Facilitates predictive maintenance by forecasting when processes may move out of tolerance.

Operational Benefits

Adopting this ML-based approach can deliver:

- Reduced process development cycles.

- Lower wafer scrap rates.

- Improved process agility when adapting to new designs or materials.

Deployment Flexibility

The trained model’s modest computational requirements allow flexible deployment:

- Edge deployment: Integration with tool controllers for real-time predictions at the equipment level.

- Cloud deployment: Use in broader fab-wide analytics and optimization platforms.

Conclusion: From Proof-of-Concept to Real-World Adoption

Demonstrating accuracy, speed, and scalability for next-generation plasma etch control

This study has demonstrated how a machine learning surrogate model can accurately predict plasma etch rates using key process parameters. Trained on a synthetically generated dataset modeled after realistic DOE, SPC, and sensor data, the neural network achieved sub-angstrom prediction errors across both training and new, unseen test data. The model generalized well, with over 92% of predictions falling within ±3 Å/min and 97% within ±5 Å/min, aligning with the precision levels required in modern semiconductor fabrication.

Beyond statistical performance, the model’s real-world value lies in its ability to:

- Reduce reliance on costly and time-consuming physical experiments.

- Enable virtual recipe tuning and rapid parameter screening.

- Support the development of digital twins and real-time process control systems.

The modest computational demands of the model make it suitable for both edge deployment on individual tools and cloud-based integration into fab-wide optimization platforms.

Looking ahead

As semiconductor manufacturing continues to confront the challenges of tighter design rules, new materials, and accelerated production timelines, machine learning offers a path to smarter, faster, and more adaptive process control.

Fabs that embrace AI-driven modeling will gain a competitive edge in efficiency, yield, and innovation.

The proof-of-concept presented here demonstrates that accurate, scalable, and practical ML solutions are not just theoretical — they are ready for real-world adoption.

Call to Action

Explore the live demo and discover custom ML solutions for your fab

The plasma etch rate prediction model featured in this article is now available as a live demonstration.

MLPowersAI develops custom machine learning models and deployment-ready solutions tailored to the unique challenges of semiconductor manufacturing and thin film processes. Our goal is to help fabs leverage their existing process data to unlock new efficiencies, improve yield, and accelerate development cycles.

In addition to semiconductor applications, we apply similar approaches to deliver custom ML models across a range of process industries, including chemical manufacturing, pharmaceuticals, food and beverage, energy systems, materials processing, and other sectors where complex process data can be transformed into actionable insights and predictive solutions.

🔗 Visit us at MLPowersAI.com

🔗 Connect via LinkedIn for discussions or collaboration inquiries.

References

Applied Materials. (n.d.). Centris® Sym3® Etch. Retrieved April 30, 2025, from https://www.appliedmaterials.com/us/en/product-library/centris-sym3-etch.html

Lam Research. (n.d.). Etch. Retrieved April 30, 2025, from https://www.lamresearch.com/products/our-processes/etch/

Lam Research. (2024, June 15). Etch essentials: The building blocks of AI era microchips. Retrieved April 30, 2025, from https://newsroom.lamresearch.com/etch-essentials-semiconductor-manufacturing?blog=true

Wikipedia contributors. (2025, March 15). Plasma etching. In Wikipedia, The Free Encyclopedia. Retrieved April 30, 2025, from https://en.wikipedia.org/wiki/Plasma_etching